Turning Waste into Wealth for Greener Fields

This technology focuses on the conversion and enhancement of goat and sheep manure, turning it into valuable resources for agriculture. By applying advanced processes, it adds economic and environmental value to these livestock byproducts, resulting in improved nutrient management and reduced waste, ultimately benefiting both farmers and the environment.

This technology is TAAT1 validated.

Open source / open access

The Processing and Application of Composted Manures technology may be of interest to Manufacturers, and users (farmers).

Manufacturers

Developing the Processing and Application of Composted Manures technology presents an opportunity to revolutionize agriculture and promote sustainability. To effectively implement this technology, consider the following steps:

As key partners, suppliers of composting equipment and raw materials for compost production are essential for successful implementation.

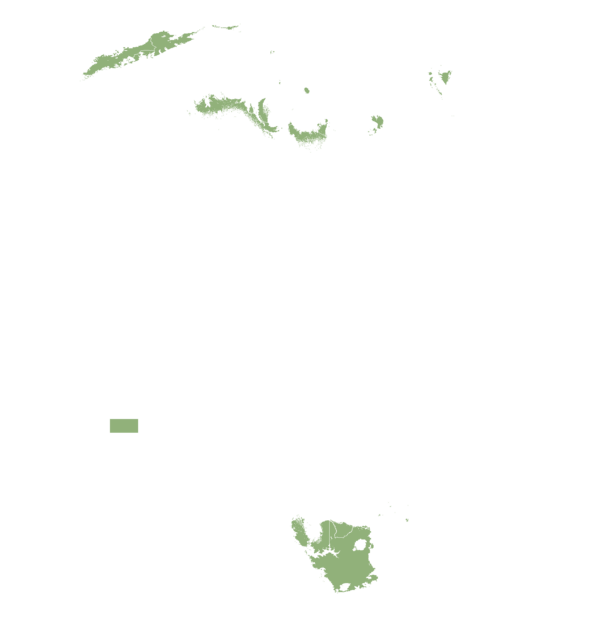

Calculate the necessary equipment for your project, considering costs and logistics. Manure drying and composting equipment able to process between 5 and 10 tons per day cost about 5,000 to 10,000 USD, including installation. Consider delivery expenses, import clearance, and applicable duties as this technology is accessible in multiple countries like Cameroon, Ethiopia, Kenya, Somalia, South Sudan, Tanzania, Uganda, Burkina Faso, Mali, Niger, Nigeria, Senegal, Zimbabwe.

Engage a team of trainers to provide comprehensive support during installation and operation. Develop communication materials to raise awareness of the benefits of composted manures.

Collaborate with breeders and local stakeholders to tailor services to market needs. Your potential customers are farmers, resellers, NGOs and development agencies

Users

Implementing the technology of Processing and Application of Composted Manures offers a sustainable solution for managing organic waste and improving soil fertility, thereby enhancing agricultural productivity and reducing environmental pollution.

As key partners, compost suppliers are essential for successful implementation.

Since the technology is accessible in various countries such as Cameroon, Ethiopia, Kenya, Somalia, South Sudan, Tanzania, Uganda, Burkina Faso, Mali, Niger, Nigeria, Senegal, and Zimbabwe, it's crucial to consider delivery costs and potential import duties.

The cost structure varies with the cost of compost.

Assessing the profitability and environmental benefits achieved through the utilization of this technology is essential.

Adults 18 and over: Positive high

The poor: Positive medium

Under 18: Positive low

Women: Positive medium

Climate adaptability: Highly adaptable

Farmer climate change readiness: Significant improvement

Biodiversity: Positive impact on biodiversity

Carbon footprint: A bit less carbon released

Environmental health: Greatly improves environmental health

Soil quality: Improves soil health and fertility

Water use: More water used

Scaling Readiness describes how complete a technology’s development is and its ability to be scaled. It produces a score that measures a technology’s readiness along two axes: the level of maturity of the idea itself, and the level to which the technology has been used so far.

Each axis goes from 0 to 9 where 9 is the “ready-to-scale” status. For each technology profile in the e-catalogs we have documented the scaling readiness status from evidence given by the technology providers. The e-catalogs only showcase technologies for which the scaling readiness score is at least 8 for maturity of the idea and 7 for the level of use.

The graph below represents visually the scaling readiness status for this technology, you can see the label of each level by hovering your mouse cursor on the number.

Read more about scaling readiness ›

Uncontrolled environment: tested

Used by some intended users, in the real world

| Maturity of the idea | Level of use | |||||||||

| 9 | ||||||||||

| 8 | ||||||||||

| 7 | ||||||||||

| 6 | ||||||||||

| 5 | ||||||||||

| 4 | ||||||||||

| 3 | ||||||||||

| 2 | ||||||||||

| 1 | ||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| Country | Testing ongoing | Tested | Adopted |

|---|---|---|---|

| Burkina Faso | –No ongoing testing | Tested | Adopted |

| Cameroon | –No ongoing testing | Tested | Adopted |

| Ethiopia | –No ongoing testing | Tested | Adopted |

| Kenya | –No ongoing testing | Tested | Adopted |

| Mali | –No ongoing testing | Tested | Adopted |

| Niger | –No ongoing testing | Tested | Adopted |

| Nigeria | –No ongoing testing | Tested | Adopted |

| Senegal | –No ongoing testing | Tested | Adopted |

| Somalia | –No ongoing testing | Tested | Adopted |

| South Sudan | –No ongoing testing | Tested | Adopted |

| Tanzania | –No ongoing testing | Tested | Adopted |

| Uganda | –No ongoing testing | Tested | Adopted |

| Zimbabwe | –No ongoing testing | Tested | Adopted |

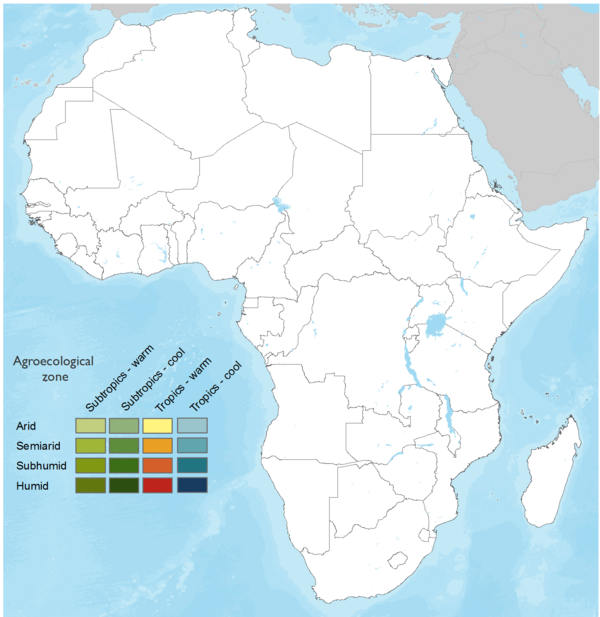

This technology can be used in the colored agro-ecological zones. Any zones shown in white are not suitable for this technology.

| AEZ | Subtropic - warm | Subtropic - cool | Tropic - warm | Tropic - cool |

|---|---|---|---|---|

| Arid | ||||

| Semiarid | – | – | ||

| Subhumid | – | – | – | – |

| Humid | – | – | – | – |

Source: HarvestChoice/IFPRI 2009

The United Nations Sustainable Development Goals that are applicable to this technology.

The production of organic fertilizer pellets from composted goat and sheep manure involves the following steps:

Last updated on 7 November 2025